7 Things You Should Know About Induction Heating

Onsite USA • September 6, 2025

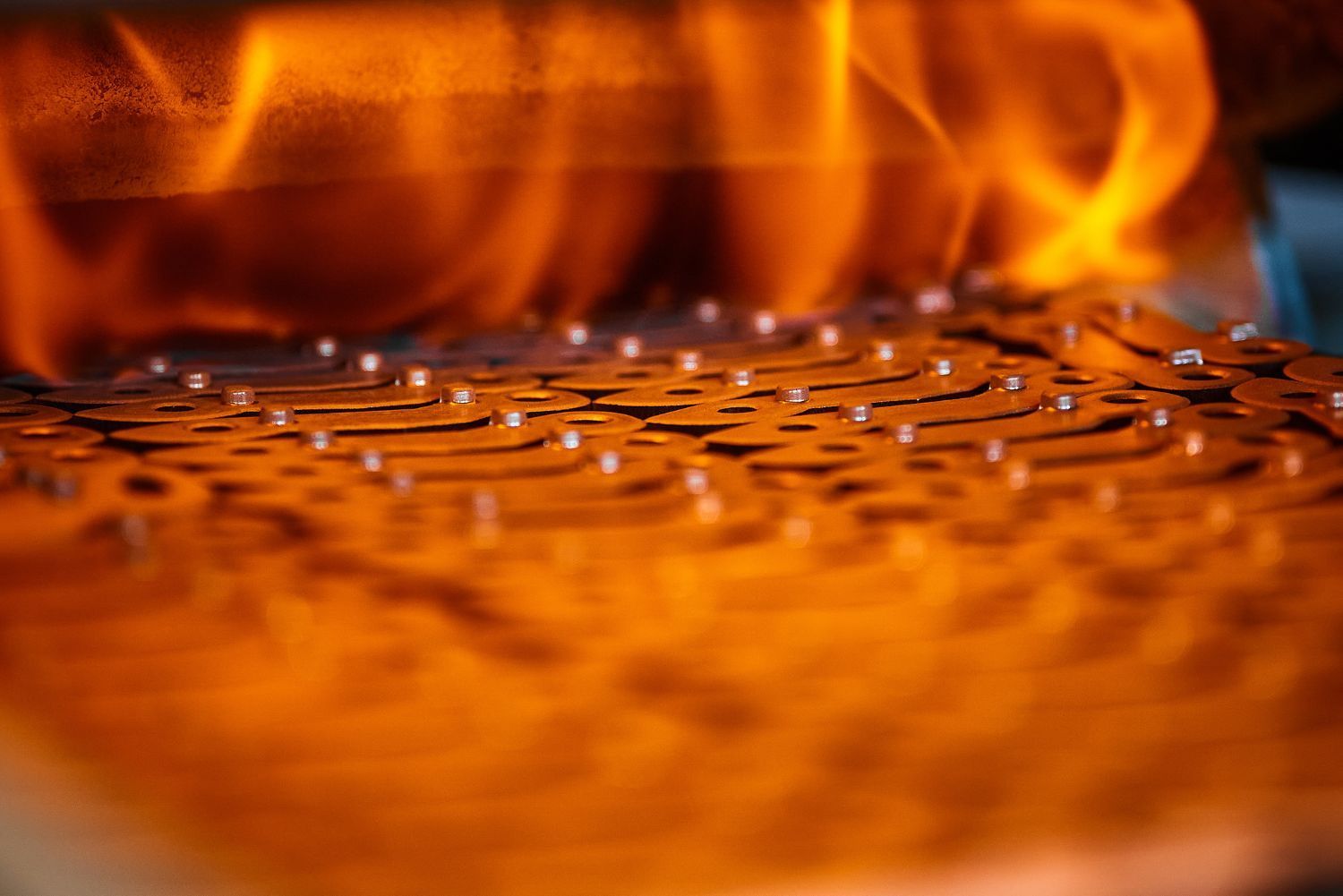

Induction heating has become a key technology in manufacturing, automotive, metalworking, and even some DIY applications. It is a fast, precise, and energy-efficient method of heating metals using electromagnetic fields. Whether you are an engineer, manufacturer, or hobbyist, understanding induction heating can help you choose the right solution for your projects and save time and money.

In this article, we cover 7 things you should know about induction heating in 2025, including how it works, benefits, applications, cost factors, and safety considerations.

1. How Induction Heating Works

Induction heating uses electromagnetic fields to produce heat directly within a metal object. Unlike traditional heating methods, the metal itself becomes the heat source due to eddy currents generated in the material.

Key points:

- No direct contact or open flame is required.

- Heating is rapid and uniform for conductive metals.

- Can be applied to localized areas or entire surfaces.

Common metals heated:

Steel, copper, aluminum, brass, and some alloys.

2. Types of Induction Heating

There are several types of induction heating, depending on the application:

- Surface Hardening: Hardens only the surface layer of steel or other metals.

- Brazing and Soldering: Joins metals without melting the entire workpiece.

- Shrink Fitting: Expands metal parts for assembly, then contracts for a tight fit.

- Melting: Small-scale melting for industrial or lab use.

Each method is chosen based on precision, speed, and material requirements.

3. Advantages of Induction Heating

Induction heating offers several significant benefits over traditional heating methods:

- Fast and Efficient: Heats metal quickly with minimal energy loss.

- Precise and Controlled: Allows localized heating without affecting the whole workpiece.

- Cleaner and Safer: No open flames or fuel combustion required.

- Reduced Material Distortion: Controlled heating reduces warping or damage.

- Environmentally Friendly: Lower energy consumption and emissions compared to conventional methods.

These advantages make induction heating ideal for modern manufacturing and repair applications.

4. Common Applications

Induction heating is widely used across industries for both manufacturing and maintenance:

- Automotive: Hardening gears, shafts, and engine components.

- Aerospace: Precision surface hardening and component assembly.

- Metalworking: Forging, annealing, and welding metal parts.

- Electronics: Soldering and joining small metal components.

- DIY and Hobbyist Use: Small-scale metalworking or tool repair.

Its versatility allows it to replace or complement many traditional heat treatment processes.

5. Factors Affecting Induction Heating Cost

The cost of induction heating in 2025 varies depending on several factors:

- Metal Type: High-conductivity metals like copper may require specialized setups.

- Size and Thickness: Larger or thicker metal pieces take longer to heat.

- Process Type: Surface hardening or brazing may cost less than melting or large-scale heat treatment.

- Equipment Quality: High-precision induction machines cost more upfront but improve efficiency.

- Volume of Work: Bulk projects may reduce per-piece cost.

Typical 2025 pricing:

Small-scale surface hardening can cost $2–$6 per pound, while industrial-scale induction melting may reach $8–$12 per pound, depending on complexity and equipment.

6. Safety Considerations

Induction heating is safer than open flames, but precautions are still necessary:

- Proper Insulation: Avoid accidental contact with high temperatures.

- Eye and Hand Protection: Wear protective gear to prevent burns or sparks.

- Electrical Safety: Ensure machines are grounded and inspected regularly.

- Ventilation: Some processes may produce fumes when metals are coated or treated.

Following these guidelines ensures safe operation for both industrial and DIY settings.

7. Induction Heating vs Traditional Heating Methods

Induction heating has several advantages over conventional methods like gas or furnace heating:

| Feature | Induction Heating | Traditional Heating |

|---|---|---|

| Speed | Very fast | Slower |

| Precision | Highly localized | Often less precise |

| Energy Efficiency | High | Moderate to low |

| Safety | Safer, no flames | Higher risk of fire or burns |

| Material Distortion | Minimal | Higher risk |

For modern industries, induction heating provides a reliable, energy-efficient, and precise solution for various applications.

Conclusion

Induction heating is a powerful, precise, and energy-efficient method of heating metals. Whether for industrial manufacturing, automotive repairs, aerospace applications, or hobbyist projects, understanding its advantages, costs, applications, and safety measures is crucial.

By 2025, induction heating continues to gain popularity due to its speed, precision, and environmental benefits, making it a smart choice for any metalworking operation. Contact a professional induction heating service today to enhance efficiency, quality, and safety in your metalworking projects.

Frequently Asked Questions

Can induction heating work on all metals?

It works best on conductive metals such as steel, copper, and aluminum. Non-conductive materials require alternative heating methods.

Is induction heating expensive?

Initial equipment can be costly, but energy efficiency and speed often reduce long-term costs.

Can induction heating be used for DIY projects?

Yes, small induction heaters are available for hobbyists, but safety precautions are essential.

Does induction heating affect metal properties?

Yes, depending on the process (hardening, annealing, or melting), induction heating can enhance strength, hardness, or malleability.

How fast does induction heating work?

Heating is almost instantaneous for small parts and very fast for larger components compared to conventional ovens or flames.