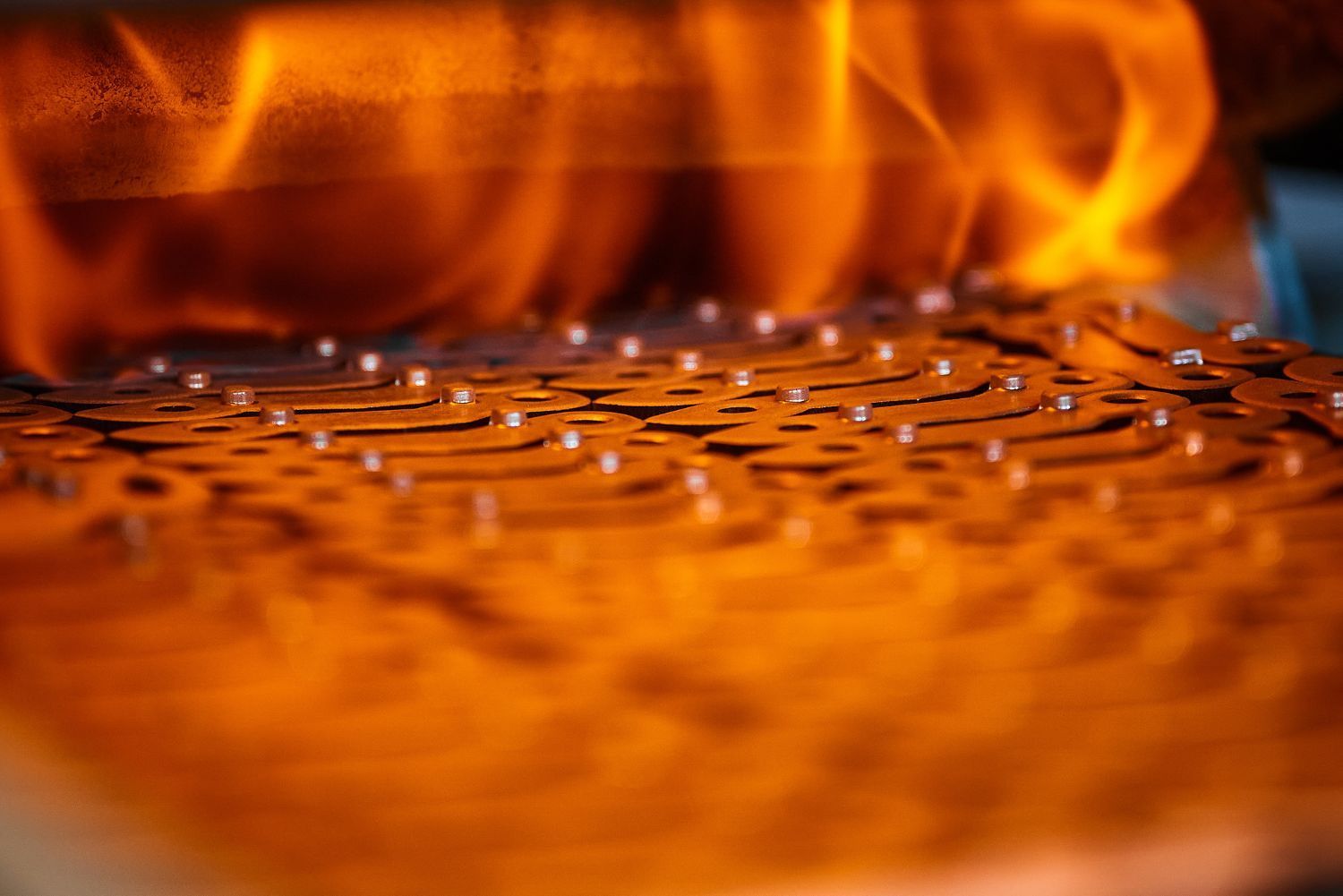

Industrial Heat Treatment Services in San Antonio, TX

In San Antonio’s high-demand manufacturing, energy, aerospace, and defense sectors, materials must meet critical performance standards. At Onsite USA, we deliver precision-engineered industrial heat treatment services in San Antonio, TX, to enhance durability, hardness, fatigue resistance, and reliability, so your parts never fail under pressure.

What Is Industrial Heat Treatment?

Heat treatment is the process of heating and cooling metals in a controlled environment to optimize their mechanical properties without altering the part's shape. These processes enhance performance by increasing:

- Hardness

- Strength

- Ductility

- Wear resistance

- Corrosion resistance

- Dimensional stability

At Onsite USA, we tailor each treatment cycle to meet precise part specifications, material types, and end-use application demands.

Our Heat Treatment Processes in San Antonio

We offer a full range of thermal processing services for ferrous and non-ferrous metals:

Annealing

Softens metal, relieves internal stresses, and enhances machinability, ideal for cold-worked or hardened parts.

Normalizing

Refined grain structure and increases toughness, commonly used for forgings, castings, and carbon steels.

Quenching & Tempering

Rapid cooling followed by controlled reheating to increase hardness while reducing brittleness, critical for gears, shafts, and tools.

Carburizing & Case Hardening

Hardens the surface layer of low-carbon steels for high wear resistance while maintaining a ductile core.

Induction Hardening

Localized surface hardening using electromagnetic fields, ideal for shafts, axles, gears, and cam components.

Cryogenic Treatment

Deep freezing down to -300°F to transform retained austenite and stabilize the microstructure, used for tooling, dies, and aerospace alloys.

Vacuum Heat Treatment

Delivers oxidation-free, scale-free hardening, ideal for stainless steels, tool steels, titanium, and aerospace-grade alloys.

Metals & Alloys We Specialize In

Our San Antonio team is experienced with a wide range of materials:

- Carbon steels (A36, 1018, 1045)

- Alloy steels (4140, 4340, 8620, 6150)

- Tool steels (O1, D2, A2, H13)

- Stainless steels (17-4PH, 410, 420, 304, 316)

Nickel-based alloys, titanium, aluminum, and exotic aerospace materials

We ensure tight control over temperature, soak time, and atmosphere for optimal and repeatable results.

Industries We Serve in San Antonio

San Antonio’s diverse industrial base includes:

Oil & Gas

We heat treat drill tools, valves, and pressure-containing components for corrosion and fatigue resistance in harsh environments.

Aerospace & Defense

Onsite USA follows NADCAP-level procedures for flight-critical and structural components used in military aviation, helicopters, and space systems.

Heat Treatment Equipment & Capabilities

At Onsite USA, we operate state-of-the-art furnaces and portable units:

- Vacuum furnaces (clean, controlled heat treating)

- Induction hardening machines

- Salt bath and gas carburizing furnaces

- Cryogenic treatment chambers

- Roller hearth and bogie hearth furnaces for batch and continuous loads

- Mobile heat treatment units for onsite repairs, stress relieving, and pipe welding pre/post-treatment

Certifications & Quality Assurance

We uphold strict industry standards and provide traceable documentation with every job:

- ISO 9001:2015 certified

- NADCAP-process aligned

- Furnace calibration per AMS 2750

- Hardness testing (Rockwell, Brinell)

- Metallurgical reports and MTRs available

You can trust our team to deliver heat-treated components that meet exacting tolerances, structural integrity, and compliance requirements.

Why Manufacturers in San Antonio Trust Onsite USA

San Antonio is home to over 1,500 manufacturing operations and multiple military and aerospace contractors, industries that rely on certified and dependable heat treatment. Onsite USA is a proven partner with:

- Decades of metallurgical expertise

- NADCAP-compliant and ISO 9001:2015 processes

- Fully equipped to handle onsite and in-facility heat treatment

- Rapid turnaround times with consistent, traceable quality

- Experience across oil & gas, automotive, military, heavy equipment, and industrial fabrication

Serving all of Bexar County, plus New Braunfels, Seguin, Boerne, and beyond.

Service Area Coverage

Onsite USA proudly serves:

- San Antonio, TX

- New Braunfels

- Seguin

- Boerne

- Universal City

- Schertz

- Cibolo

- Converse

- Kerrville

- And surrounding Central Texas cities

Need mobile services? We dispatch onsite heat treatment teams directly to your facility or jobsite.

Request a Quote for Industrial Heat Treatment in San Antonio

Don’t compromise on quality or timelines. Choose Onsite USA for precision, performance, and professionalism in every thermal cycle.

Call 346-291-2058 or request a quote to speak with a specialist and get a fast, competitive estimate.

Industrial Heat Treatment - San Antonio, TX

FAQs About Industrial Heat Treatment

What is industrial heat treatment?

It’s the process of heating and cooling metal to change its physical and mechanical properties like hardness, strength, and ductility without changing its shape.

How much does heat-treating cost?

Cost depends on the material, size, and type of treatment. It typically ranges from $0.50 to $5.00 per pound or by batch for large production runs.

What are the 4 types of heat treatment?

The most common types are annealing, normalizing, hardening (quenching), and tempering, each used to tailor the metal’s properties for specific applications.

What is the difference between surface treatment and heat treatment?

Heat treatment changes the entire metal structure, while surface treatment only modifies the exterior to improve appearance or corrosion resistance.

What is the difference between annealing and normalizing?

Annealing softens the metal for machining, using slow furnace cooling. Normalizing improves strength and toughness through faster air cooling.